We’ve been trying to sort out a laser cutter for a while now, last year we bought a 40W tube and a PSU and burned holes into things. While hugely entertaining, it lacked some precision

(edit: fixed boken links)

That was as far as it went, so i had enough and just decided to order one, after a few stops and starts we bought an LC900N directly from wklaser in China, they’re the same ones FS laser and hurricane etc sell but they do some mods to the software/boards, but nothing that is worth the price increase that i can see. It cost us under $4,000 USD for a 90W laser with a 600x900mm cutting area, with a motorised Z table from china to us.

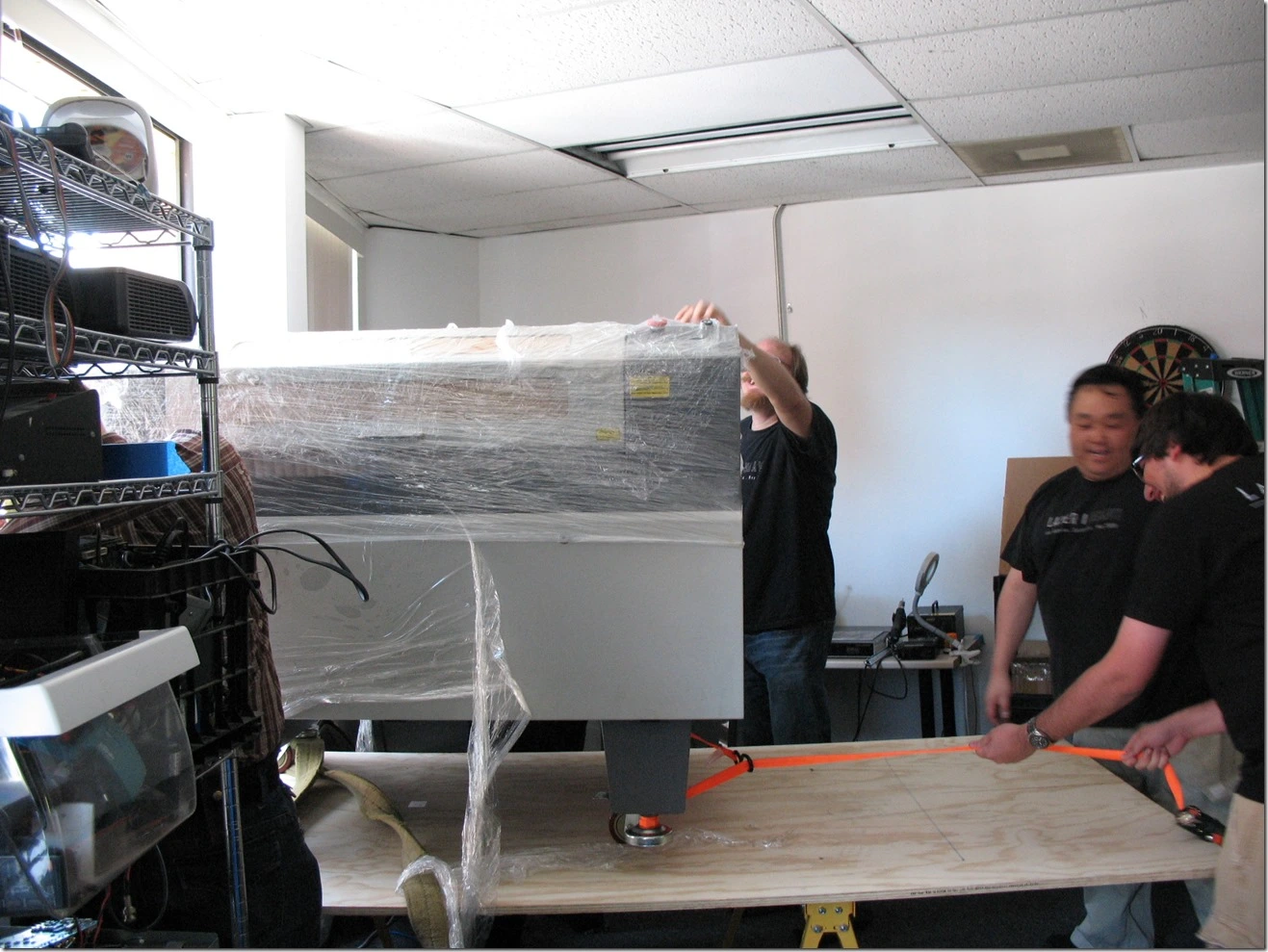

We’re on the third floor and our elevator is ( A ) too small ( B ) out of order, so we had to levitate it in.. Having hindsight we could have taken it apart, but had been previously assured we couldn’t do that. Anyway…..

We did what anyone would do and removed the window, hired a crane and lifted it in through the window.

Taking it out to inspect the contents etc.

Building a landing table

Scientific weight test, the window is gone and 3rd floor, proceed to start jumping. Some people were confused about what don’t go past the blue line meant.

Yes this is a good idea.

Test lift

We put out cones, people removed them and parked anyway, I told a few people they may not want to park there, most people got annoyed and asked why not? So i explained, most of them changed location. But only most….

ok we’ve gotten it to here, what now ? Time for a meeting.

The tricky part, removing the first strap, everyone pitched in to help.

The Rapunzel method started off well but we discovered a problem in the hair length dept.

And its in!

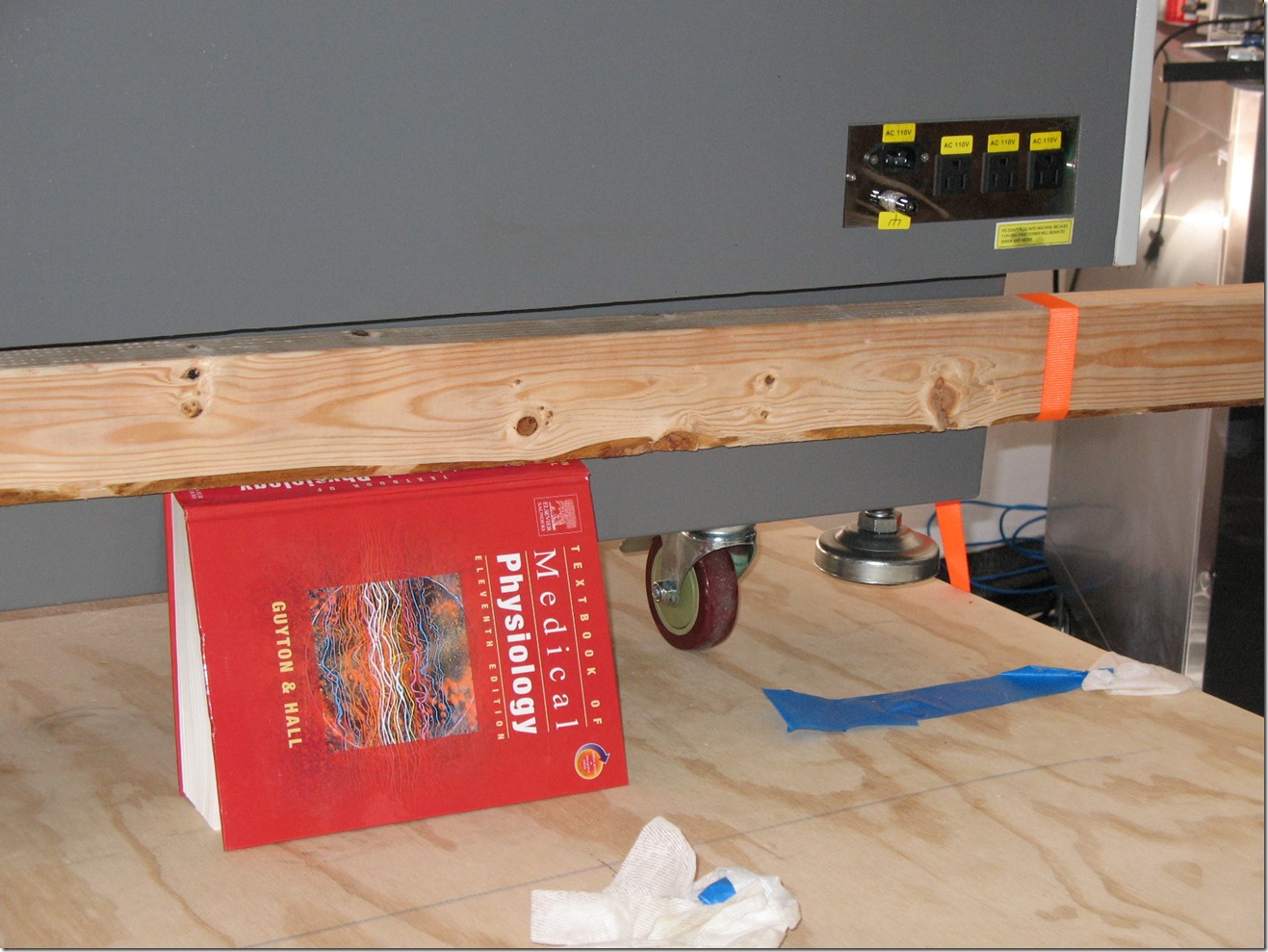

Books are useful. Dropping it the last meter was harder than getting it from China.

Put the window back, respackle it and no one is the wiser.

Ok so the laser is purchased, shipped from china, craned in through a window. What next?

First install the tube

The laser needs a vent, preferably hilarious. (needs video)

Obviously take it apart and improve it.

The height setting tool needed improvement, so made that and labelled it as such

Test cuts. Lots of test cuts.

Align mirrors, the manual came in useful here. (bits of paper)

Now change mind, remove the mirrors, turns out they’re dirty! So we swapped them out for ii-iv’s, increasing the power 20%. Interestingly there is a technique to make CO2 laser mirrors from hard drive platters hard disk platter co2 laser mirror

Frostbite hand.

The new lens vs old one.

Ply Wood 5.2mm 8speed 90power OLD LENS

ply wood 5.2mm 15speed 40power NEW LENS

The T4 28” fluorescent bulb burned out after a day or so so we replaced it with some halogens, especially since they’re hard to source locally, test fitted with duct tape. The whole machine gets covered in grease for shipping so lots of cleaning first.

Next well they said we can’t cut steel. So quick trip to home depot for some O2.

The glo-stick is vital

well it is cut but…. not really useable, however great progress

vertical video!

Here we cut some 1” acrylic

Next!

The GUI is full of odd chinese-english conversions, but they use a UTF8 .ini file so you can edit it all you want. Instead of Datum, it is now Home . Just edit language.ini or use Resource Editor on the .exe for permanent changes the software does nt self check, even though it uses a senselock dongle.

Next is hack the software, we figured out the control software, reversed most of the API it actually rasterises vectors in the PC side and sends them over as points!! I’m shocked and amazed since the machine has a ‘DSP’ based controller board. It generates a TXT file and compiles it ,then uploads it the API has move, p-move, arc and circle functions but the software never uses them..

e.g.

CLASS_DECLSPEC int APICALL M05_m_fast_line2(int chx,long disx,int chy,long disy);

CLASS_DECLSPEC int APICALL M05_m_set_vector_profile(double ls,double hs,double ac);

CLASS_DECLSPEC int APICALL M05_m_set_vector_profile2(double start_ls, double hs, double end_ls, double ac, double dc);

CLASS_DECLSPEC int APICALL M05_m_curve_vertex();

CLASS_DECLSPEC int APICALL M05_m_curve_begin();

CLASS_DECLSPEC int APICALL M05_m_curve_end();

CLASS_DECLSPEC int APICALL M05_m_set_period(double period);

CLASS_DECLSPEC int APICALL M05_m_set_power(int LowPower,int HighPower);

CLASS_DECLSPEC int APICALL M05_m_set_laser_mode(int mode);

The are all set ramp speeds, laser on, move here, move here move here, move here. Not set point, radius calculate in controller.

Oddly the first command we figured out (unintentionally) was fire the laser at full power indefinitely.

Is it off, no, is it off now , no ? how about now ,, no ? OK what’s the tube temp? still not off ? Easy to fix though, its just a toggle on/off. You also can’t easily jog the laser head around with the laser on, it’ll work but you can’t turn it off easily!

Knock out a quick GUI in Visual Studio.

I updated the header file for the DLL on our SVN. I’ll document it as i go along

Example of the txt file, which it compiles on the PC side.

SUB001

CMD101,0

SET002,20000

SET014,1,0,2,2

CMD109,1

CMD102,416,20833,97222

CMD104,6944

CMD401,416,880,41666,900

CMD402,900

CMD409,416,880,3000,41666,900,5000 //set ramp speeds and power

CMD408,900,5000

CMD050,2,1

CMD002,63556,42631

CMD050,1,1 //laser on

CMD103,416,41666,69444

CMD001,63556,42631 // move

CMD050,1,0 //laser off

i’m surprised it rasterises the vectors though, i was expecting to see a command for a circle that defined a center,radius etc.

speed change. 100 to 300

CMD401,416,880,13888,900

CMD409,416,880,3000,13888,900,5000

CMD103,416,13888,69444

CMD401,416,880,41666,900

CMD409,416,880,3000,41666,900,5000

CMD103,416,41666,69444

power change 9 to 99 ( *100)

CMD401,416,880,13888,900

CMD402,900

CMD409,416,880,3000,13888,900,5000

CMD408,900,5000

CMD401,416,880,13888,9900

CMD402,9900

CMD409,416,880,3000,13888,9900,5000

CMD408,9900,5000

horizontal line moved in y

CMD002,62466,45271

CMD001,62466,45271

CMD001,69328,45271

CMD002,69328,45271

SUB603,416,20833,97222,69328,45271

CMD001,69328,45271

CMD001,69328,45271

CMD001,62466,45271

CMD001,62466,45271

CMD001,69328,45271

CMD001,69605,44993

CMD001,69605,45548

CMD001,62188,45548

CMD001,62188,44993

CMD001,69605,44993

CMD002,62466,45175

CMD001,62466,45175

CMD001,69328,45175

CMD002,69328,45175

SUB603,416,20833,97222,69328,45175

CMD001,69328,45175

CMD001,69328,45175

CMD001,62466,45175

CMD001,62466,45175

CMD001,69328,45175

CMD001,69605,44898

CMD001,69605,45453

CMD001,62188,45453

CMD001,62188,44898

CMD001,69605,44898

horizontal line moved in x

CMD001,69328,45271

CMD002,69328,45271

SUB603,416,20833,97222,69328,45271

CMD001,69328,45271

CMD001,69328,45271

CMD001,69328,45271

CMD001,69605,44993

CMD001,69605,45548

CMD001,69605,44993

CMD001,69492,45271

CMD002,69492,45271

SUB603,416,20833,97222,69492,45271

CMD001,69492,45271

CMD001,69492,45271

CMD001,69492,45271

CMD001,69770,44993

CMD001,69770,45548

CMD001,69770,44993

Lots of boxes were cut

boxmaker scripty thing

Found a nice dragon box on thingverse

bVector made a nice mod to that case.

So this ends our first week with the cutter, we have to decide if we’re replacing the controller, Leetro apparently want us to buy $25,000 of stuff to get the SDK documentation, but we’re so far into reversing it, that won’t matter. The controller might be ok. It has some strangeness we want it to speak GCODE so maybe another GRBL based controller like we did for Pickobear.

We’re also building a new frame for it, and updating it to 170W laser tube (maybe)

more to come….

Great post & congrats on getting yourselves a laser!!! I bought a laser 18 months ago from WKLaser and had a wonderful experience dealing with them. Oh, and I had to remove a window to get my laser inside, too 🙂

Nice article, thank you for posting. I wonder what kind of lense did you buy to get such an increase of power? Thanks + keep up the good work!

http://www.iiviinfrared.com/

I’m curious (and surprised about your modest successes cutting steel. I had heard that (due to the reflectivity of the molten steel?) attempting it can damage the laser or the head/nozel/lens and that metal-cutting CO2 lasers have an additional polarizing filter system to control the reflections. Have you noticed any problems since cutting steel? Or any plans to improve the cuts in the future?

The mirrors and the last part of the laser ( the focus stage ) are consumable basically, the very last stage will get eaten simply away with the heat etc, so we are looking to change them out to a copper ends and increasing the lasers power. We will probably only keep cutting the same thin steel but its useful for us. The 170W tube should get us where we want to be.

How about this as a technique for metal mirrors?

http://diylaser.midwestlaserarts.com/2012/01/get-your-co2-laser-mirrors-for-free.html

Perhaps not the best reflectivity, but if it’s essentially a consumable that wouldn’t matter.

What thickness of steel was that?

Err, that link is in the article 🙂

Just over 1mm I believe, everyone I work with here still uses imperial…

Awesome! Keep us up to date on the controller reversing – I’ve got one with an MPC6535 controller and the lasercut software can be quite limiting and badly behaved on occasion.

Congrats guys, wish I was still in LA to see this and help reverse that controller app, sounds like fun. I volunteer for the first NSL laser tattoo, just spray my arm with flat black spraypaint. (semi-serious here) Remind that distinguished rapist enzo to send me the nsl stickers! (he promised)