I used a BusPirate V3 board to test out these rivets. They are effectively thru-plating for PCB’s, normally you need to do messy multistage chemical stuff to do it at home. This isn’t as good a result as a chemical plate but it makes up for it in ease of use. It’s not the cheapest option, which is usually just using a bit of wire in the hole and hand soldered in, but that can cause problems with VIA’s under flush mounted components.

Basically you put a rivet in the hole, flip it over and hit with an automatic center punch.

LPKF Store

http://www.lpkfusa.com/store/pages/list.aspx?cat=10/31&cid=31

BusPirate Dangerous Prototypes ( Buy one of them at http://www.seeedstudio.com/depot/preorder3-bus-pirate-v3-assembled-p-579.html and support the effort Ian is making )

http://whereisian.com/forum/index.php?board=4.0

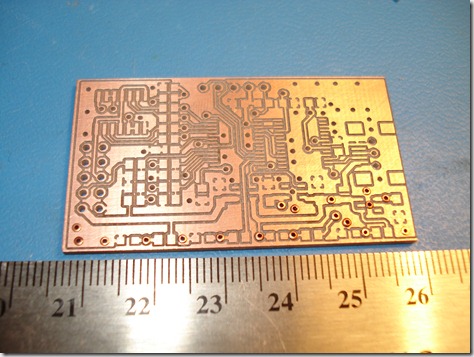

Here are some of the results so far. I didn’t spend as much time as i ought to have aligning the backside of the board, so the drills are slightly off.

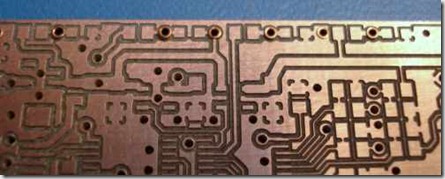

TopSide

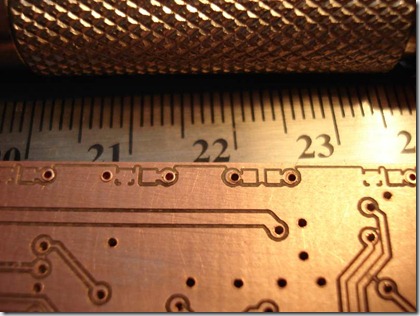

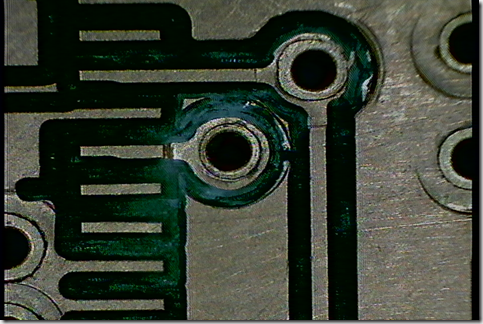

Bottom side, they take up less space on the side that’s being compressed.

I used a needle to insert them one a time, a wire strung with a bunch might work.

A few more added.

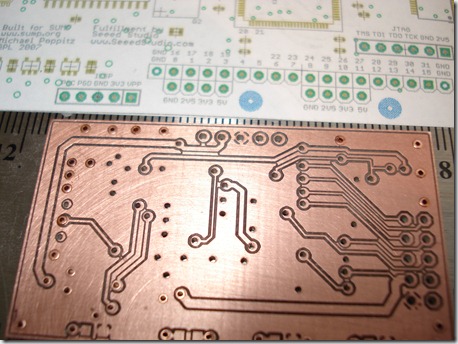

Takes a little practice to get them smooth, making the automatic center punch ‘snap’ is key. They’re almost flush when that happens. (circuit in the back is Jack Gassett’s butterfly (the logic analyser update for the sump) http://blog.gadgetfactory.net/ )

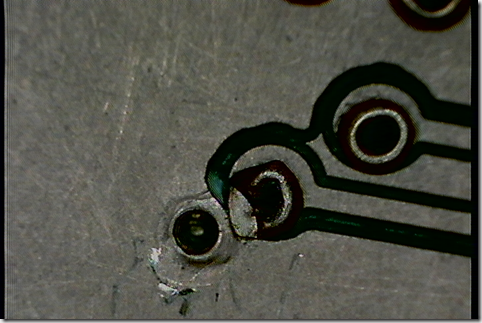

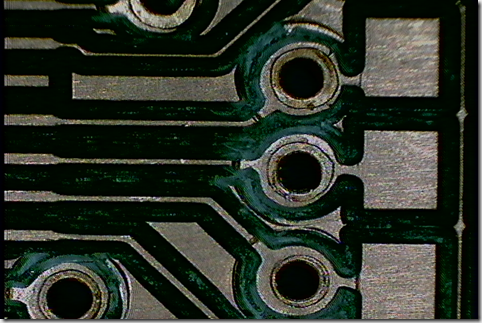

some closeups with the HiView wireless usb microscope, because of the way it works you see black rings where there is really copper if its an angle.

This one went funky, needs some after attention, I didn’t put the center of the punch in the rivet !

trying out different pressure settings on the punch

So these guys work solely via (pun intended) their mechanical connection to the clad?

yep, but given the pressure involved they’re not going anywhere. Plus you can make the via pads bigger and solder them too. they practically fuse.

Nice things but INSANELY expensive in sweden. Kit with ~4000 rivets and tool is almost $1000. (yes $1000!!)

they’re pretty expensive here too.

You can easily make copper via rivets yourself, and it’s not expensive, and they are easy to place. I wrote an article about this on paulwanamaker.wordpress.com

it looks like you’re using solid core wire and the soldering them in, that works for a lot of stuff but the problem is if you do any reflow they typically fall out again the rivets mechanically make a joint so you’re not worried about that. but we use the wires too when we dont need that,

cheers